Hotronix® Dual Air Fusion™ Heat Press

$8,150.00

Hotronix® Dual Air Fusion™ Heat Press

Hotronix® Dual Air Fusion™ Double-Down on Performance The Hotronix® Dual Air Fusion™ doubles down on performance, giving you 50 percent more productivity than a standard swinger-style heat press.

Call Details for

Description

Hotronix® Dual Air Fusion™ Heat Press

Increase Production By At Least 50%

16″ x 20″ Dual Quick Change Platens

Freight Quoted separately

a $200 crating fee will be added to the freight cost

Call Details for Special Promotions

Hotronix® Dual Air Fusion™ Double-Down on Performance The Hotronix® Dual Air Fusion™ doubles down on performance, giving you 50 percent more productivity than a standard swinger-style heat press. With groundbreaking A and B workstations that operate independently or in unison, you get the additional performance of an extra heat press while maximizing time and space. With the inclusion of a second platen, the Dual Air Fusion doubles down on proven Hotronix® technology and takes performance—and profits—to the next level.

The Dual Air Fusion includes a laser alignment system that puts your jobs on target, each and every time. Four independently-adjustable lasers per platen enable precision alignment of graphics for full-front, left chest and numerous other applications. The system seamlessly integrates into the Dual Air Fusion’s workstations and is controlled entirely through the touchscreen—power on or off and choose between dual or independent operation. Quickly and easily position graphics for any heat printing job with the Laser Alignment Wizard™. Align each individual bulb of the Laser Alignment System to one of five popular layouts or use the rulers for custom placement. Follow the L.A.W. with this heavy-duty, spiral bound template to achieve consistent placement of heat printing designs and transfers every time.

• Dual 16″ x 20″ Quick Change platens • A and B workstations – operate independently or in unison • Touchscreen control panel with programmable settings • Industry-leading warranty

220 volt only

Auto-Adjust Pressure™ automatically adjusts to the thickness of the item being printed

Full Threadability™ on the lower platen: position the garment, rotate, and decorate any area

Dual platens allow a heat-free workspace on one platen while the other is being pressed

Perfect for Direct-to-Garment printing – cut production time in half by programming one station for pre-treatment and the other for curing

Rodless transmission for smooth, quiet operation

Operates in full-auto, semi-auto, or manual modes

Laser alignment system included, helps ensure accurate placement and alignment

Touch screen stores frequently used settings, production cycle counter, and auto on/off capability

120 PSI for high pressure applications

Optional quick-change platens; no tools required

Program up to four different pressure and time settings

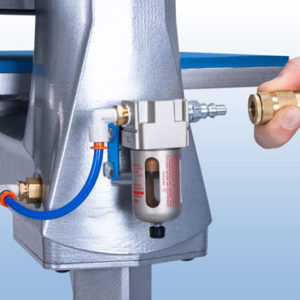

Requires air compressor (not included) with minimum 1 horsepower and 5 gallon hold tank. Uses 2.3 CFM

Recommended table size: 24″ x 36″ x 28″ with 30″ height

Freight Quoted separately, truckline only

Universal Features

Made in the USA

Cast-in tubular heating

Powder coated finish

UL/ULC/CE/RoHS compliant

Details

Actual weight: 260 lbs.

Ship weight: 500 lbs.

Ship dim. 45.5” x 45.5” x 33.5”

Optional Platens

7″ round

6″ x 10″

8″ x 10″

11″ x 15″

Additional information

| Dimensions | 40 × 40 × 25 in |

|---|---|

| Selections | 4"x4" Platen, 6"x10" Platen, 7" Round Platen, 8"x10" Platen, Compressor, Lift gate needed, No Accessories needed, no extra platens, No lift gate needed, Pedistal, Set of Platens |